Why Thermoformed?

When a Highly Durable Sign is RequiredThe Challenge – Photopolymer Failure

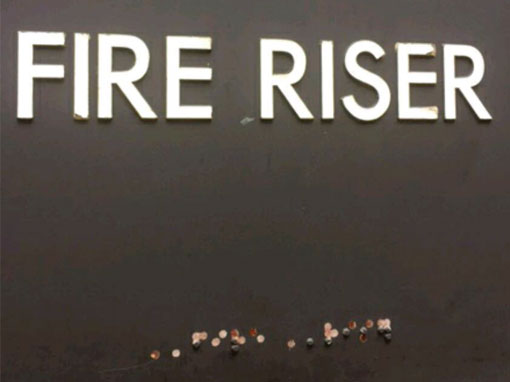

The ‘Fire Riser’ picture shows an example of a photopolymer ADA sign that is coming apart due to moisture. Photopolymer is a water etched, UV activated material.

Many designers and architects are no longer including photopolymer signs in their projects because of this. Mostly, they want to ensure their clients have the most durable, functional and sustainable signage available!

The Solution – Thermoformed Signs

Thermoformed signs are guaranteed not to fail for the life of your building. And that’s just the start!

Thermoformed Sign Advantages

Weather Resistant

Thermoformed signs are cast as a single piece that is solid and will never decay or delaminate.

Impact Resistant

They can withstand high impact and are scratch, chip, dent resistant making them perfect for high traffic applications

High Density Plastic

High density plastics are not damaged by cleaning agents making them ideal for medical settings.

Clean Persistence

Fingerprint and graffiti resistant

%

More Cost Efficient

%

More Applications

%

More Durable

Single, Solid Piece

Advantages of Thermoforming vs. Photopolymer

|

Thermoforming |

Photopolymer |

|

|

Spherical Braille Shape |

YES |

NO |

|

Subsurface Paint |

YES |

YES |

|

Solid One-Piece Construction |

YES |

NO |

|

Paint Coat Required |

NO |

YES |

|

Exterior Rated for Subsurface |

YES |

NO |

|

Multiple Substrates Available |

YES |

YES |

|

2010 Dual Purpose Capable |

YES |

NO |

|

Raised Custom Graphics & Logos |

YES |

YES |

Contact LK Wholesale Today!

Contact LK Wholesale about all of your interior and ADA sign requirements.

Let us submit a competitive bid on your next project!